- Oil Mill Machinery

- Oil Refinery Machinery

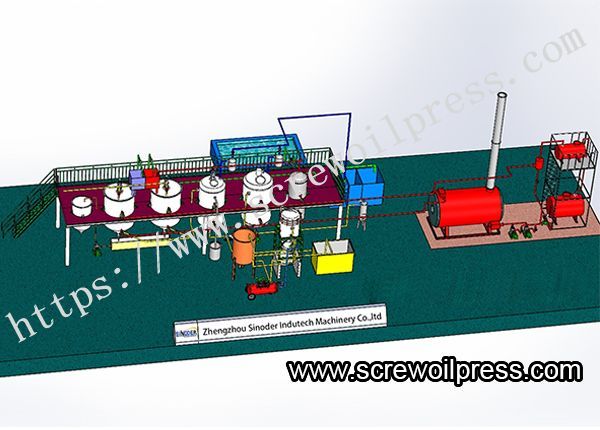

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

NEWS

Why Do Refining Equipment Usually Have Several Refining Tanks?

Time:Fri-11-21 hits:

For some customers who are new to the industry but are not familiar with all aspects, they often ask why there are four refining tanks when purchasing equipment. I don't have enough budget, can three refining tanks work? I think others only have two refining tanks.

For this question, please listen to our explanation first.

The oil refining process usually has several steps, but there are mainly four steps: dephosphorization, deacidification, decolorization, and deodorization.

Let's take a look at the functions of the refining equipment of the four tanks.

Let's take a look at the functions of the refining equipment of the four tanks.First of all, the functions of the refining equipment of the four tanks are dephosphorization and deacidification, dry dehydration and decolorization, and the last refining tank is vacuum deodorization. After this set of equipment is installed, it is very easy for the edible oil standard to meet the national standard.

Details: Two tanks for dephosphorization and deacidification, one tank for drying and dehydration, and one tank for deodorizing.

Of course, there are not only these four types of refining, but also degumming, dewaxing and so on. They are all planned based on oil.

If you have any questions about the product, you can communicate with us. Please trust us. In addition to providing complete sets of processing equipment, we also provide program construction, installation, commissioning and operation training. Let you have the best experience before, during and after sale.