- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

NEWS

The Function And Principle Of The Branch Cylinder

The process of oil pressing varies according to the different raw materials of oil pressing.

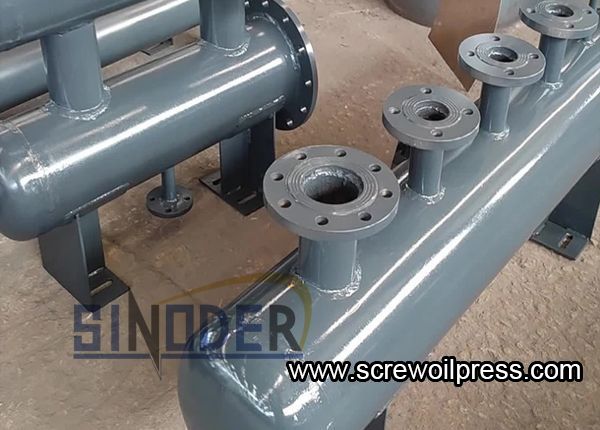

The branch cylinder is one of the main auxiliary equipment of the boiler.

It is used to distribute the steam generated by the boiler during operation to the various pipelines. It is a pressure vessel belonging to the cylinder system, and its pressure bearing capacity and capacity should correspond to the supporting boiler.

The main pressure components of the cylinder are: head, shell material, etc.

Sub-cylinder Performance Structure

The sub-cylinder is the key supporting facilities and equipment of the heating furnace, which is used to distribute the steam caused by the boiler operation to the various pipelines. The sub-cylinder is the machine equipment that bears the pressure and belongs to the high-pressure vessel.

The key role of the sub-cylinder is to distribute steam, so there are several high-pressure gate valves on the sub-cylinder to connect the main steam valve of the heating furnace and the steam distribution gate valve, which is convenient to distribute the steam in the sub-cylinder to the necessary places.

The main pressure components of the sub-cylinder are: steam distribution valve seat, main steam valve seat, safety valve seat, relief valve seat, pressure gauge seat and thermometer seat.

Sub-cylinder Working Principle

1. Gravity Separation:

Solid materials in the water and air medium with the separation and separation process based on the law of gravity movement, in the field of waste treatment and recycling can be generally divided into gravity sedimentation and gravity separation processes;

2. Inertial Separation:

The separation is carried out by the inertial force when the water mixture changes the flow direction.

3, Centrifugal Separation:

The separation is carried out by the centrifugal force generated when the mixture of water and water rotates.

4, Water Film Separation:

Water droplets in the mixture of steam and water adhere to the metal wall, forming a water film flow down and separate.

Through the principle that water droplets in the soda mixture can adhere to the metal wall, the formation of water film flows down and separates.

The process of water separation in the drum is generally divided into two stages: the first stage is the crude separation, which is the task of separating a large amount of water and steam and eliminating the kinetic energy of the water mixture; The second stage is the fine separation, whose task is to reduce the humidity of the steam.

Split Cylinder Action

1. The function of storing steam and regulating gas pressure;

2, the steam body shunt effect, through the branch cylinder can make the pressure balanced out of the multiple branch pipe for different steam equipment for steam;

3. The diameter of the sub-cylinder tank is larger than that of the pipeline, and the flow rate of the heat medium entering the sub-cylinder through the pipeline is greatly reduced. The impurities in the steam body are separated and sunk to the bottom of the sub-cylinder tank through the steam water, and then discharged to the sewage sump through the sewage pipe;

4, the branch cylinder is like the air compressor storage tank, the larger the diameter of the tank, the larger the volume, the better the balanced pressure regulation effect and effect.

What are the uses of the sub-cylinder?

The sub-cylinder, also known as the sub-cylinder, is widely used in petrochemical, power generation, steel, cement, construction and other industries, and is an indispensable auxiliary equipment for steam boilers.