- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

NEWS

What are the differences between soybean oil presses, leaching & refining

Soybean oil press, soybean leaching equipment and soybean oil refining equipment have obvious differences in working principle, structure, application scenarios and product characteristics.

Working principle

Soybean oil press: Using the principle of mechanical extrusion, through the rotation of the spiral shaft to promote the soybean to move forward in the press chamber, in this process, due to the gradual reduction of the press chamber space, great pressure is applied to the soybean, so that the oil is squeezed out from the soybean cells to achieve the separation of oil residue.

Soybean leaching equipment: According to the extraction principle, the use of organic solvents (such as n-hexane) to soak or spray the pre-treated soybeans, so that the oil in the soybeans is dissolved in the solvent, forming a mixed oil, and then through evaporation, stripping and other operations, the solvent and oil separation, so as to obtain soybean crude oil.

Soybean oil refining equipment: based on different physical and chemical principles, remove impurities, phospholipids, free fatty acids, pigments, odors and so on in soybean crude oil.

For example, phospholipids are removed by hydration degumming, free fatty acids are neutralized by alkali refining, and pigments are removed by adsorption.

Structural composition

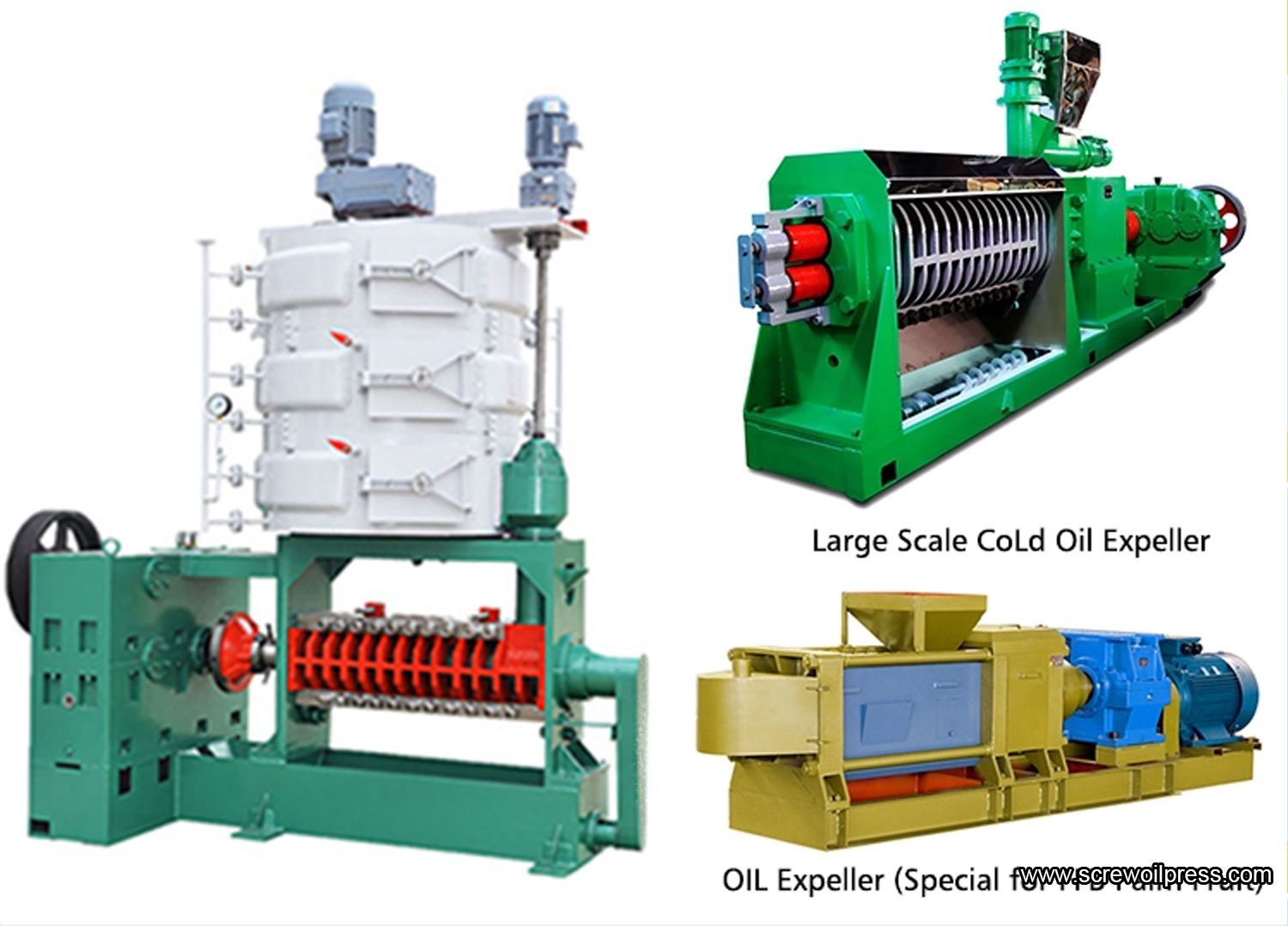

Soybean oil press: mainly composed of hopper, spiral shaft, press chamber, cake outlet, oil outlet and other parts.

The screw shaft is the core component, and its pitch and diameter are designed to vary according to the pressing needs.

Soybean leaching equipment: usually includes extractor, evaporator, stripping tower, condenser, solvent turnover tank, etc.

The extractor is the main equipment, there are many types of horizontal rotary, ring and so on.

Soybean oil refining equipment: generally includes hydration tank, alkali refining tank, decolorization tank, deodorization tower, etc.

It is also equipped with auxiliary devices such as filtration equipment, heating and cooling system.

Application scenario

Soybean oil press: suitable for small oil mills or places that do not have high requirements for oil production and pursue traditional press flavor, such as some rural oil mills and characteristic oil processing shops, which can produce pressed soybean oil with unique flavor.

Soybean leaching equipment: often used in large oil processing enterprises, can handle soybean raw materials on a large scale, can efficiently extract oil, improve oil yield, suitable for cost control and production efficiency requirements of higher industrial production.

Soybean oil refining equipment: Whether it is a small oil mill or a large oil enterprise, as long as it needs to produce high-quality edible soybean oil that meets national standards, it is necessary to be equipped with soybean oil refining equipment to refine pressed oil or leached oil.

Product characteristics

Soybean oil press: The produced soybean oil has a rich bean flavor, but the oil yield is relatively low, and the oil may contain more impurities, requiring further filtration and other treatment.

Soybean leaching equipment: high oil yield and fast production efficiency, but the extracted soybean crude oil contains impurities such as solvent residues, which need to be refined before consumption.

Soybean oil refining equipment: the refined soybean oil is clear and transparent, light color and no odor, in line with national edible oil standards, good stability and long shelf life.