- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

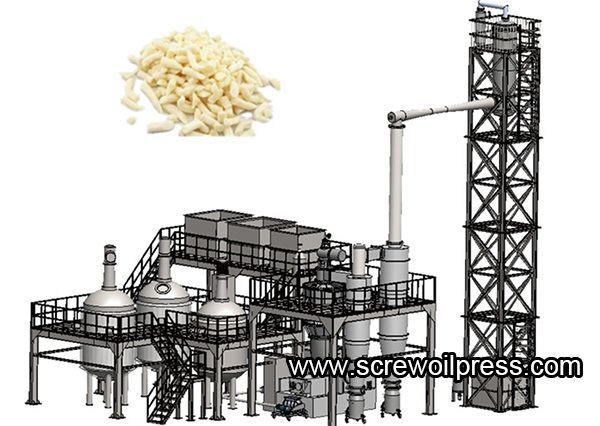

Oil Processing Plant

Peanut Oil Press Plant Groundnut Oil Extraction Peanut Oil Refining Plant

Provide the equipments to process different capacity of peanut groundnut They bring unrivalled experience to bear in producing accurate drawings detailing foundation loadings, building dimensions and overall plant layout designs, tailor made to

SEND INQUIRY

Description

Groundnut /Peanut Oil Pressing, Peanut Oil Extraction and Oil Refining Plant

We can provide the equipments to process different capacity of peanut/ groundnut.

We are involved in providing machinery that is capable of processing different varieties of nuts and oil seeds. These extracted oils are further used in aromatherapy, skin care products, food items and many others. The oil processing includes cleaning of seeds, clarification, extraction, packaging and storage. The process differs for variety of seeds. We are here defining the process that is used while extracting the oil from various types of nuts and oil seeds.

Peanut or Groundnut Oil Pressing, Extraction and Refining Plant or the whole processing line working procedures:

1. Groundnut oil press process:

A. Groundnut →magnetic roller→Destoner→screening→grading( small group with higher quality and big group with normal quality)

-Magnetic roller is to remove metallic impurities.

-Destoner is to remove small stones.

-Screening is to remove other impurities.

-Grading is to divide groundnut into small group and big group.

B. Small group groundnut→cooking→pressing→crude oil→degumming→ first filtering →Second filtering→strong fragant edible groundnut oil

-Cooking: to change physical characters of groundnut in order to improve oil yield.

-Pressing: to press groundnut , get crude oil and oil cake

-Degumming:to make phosphatide absorb water and precipitated.

-First filter: to remove impurities and part of phosphatide

-Second filter: to remove phosphatide reaching national standard.

C. Big group groundnut →crushing →flaking →steam cooking →pressing → crude oil →degumming→ first filtering →Second filtering→edible groundnut oil

- Crushing : to crush groundnut into 4-6 pieces which fits flaking conditions

- Flaking : to flake crushed groundnut into thin and even pieces, thickness < 0.5mm

- Cooking , pressing until edile groundnut are same as above.

2. Groundnut oil extraction process

Pressed groundnut oil cake → Oil extractor→ Mixed oil→ Three evaporation→ Crude groundnut oil

|

wet meal → desolventizer → dry meal to package

- Oil extractor: using solvent N-hexane to extract oil from pressed oil cake

- Mixed oil/wet meal : after oil extractor, will get mixed oil with solvent and wet meal with solvent

- Three evaporation: using three muti-effective evaporators to transform solvent to gas which will be cooled down and collected by passing condensers.

- Desolventizer: to dry wet meal and evaporate solvent .

3. Groundnut oil refining process

Crude oil from oil extraction→ Degumming → Deacidification→Decoloration→ Deodorization→Refined groundnut oil

- Degumming: adding phosphoric acid (85%) to reduce gum and impurities inside crude oil

- Deacidification: adding alkali to neutralize free fatty acid , generates soapstock

- Decoloration: adding clay to bleach crude oil , clay quantity depends on quality of decoloration . Waste clay will be filtered .

- Deodorization: at high temperature vacuum conditions, using steam to remove odor impurities

if you want to know more the Groundnut /Peanut Oil Pressing, Peanut Oil Extraction and Oil Refining Plant, pls feel free to contact us.

We can provide the equipments to process different capacity of peanut/ groundnut.

We are involved in providing machinery that is capable of processing different varieties of nuts and oil seeds. These extracted oils are further used in aromatherapy, skin care products, food items and many others. The oil processing includes cleaning of seeds, clarification, extraction, packaging and storage. The process differs for variety of seeds. We are here defining the process that is used while extracting the oil from various types of nuts and oil seeds.

Peanut or Groundnut Oil Pressing, Extraction and Refining Plant or the whole processing line working procedures:

1. Groundnut oil press process:

A. Groundnut →magnetic roller→Destoner→screening→grading( small group with higher quality and big group with normal quality)

-Magnetic roller is to remove metallic impurities.

-Destoner is to remove small stones.

-Screening is to remove other impurities.

-Grading is to divide groundnut into small group and big group.

B. Small group groundnut→cooking→pressing→crude oil→degumming→ first filtering →Second filtering→strong fragant edible groundnut oil

-Cooking: to change physical characters of groundnut in order to improve oil yield.

-Pressing: to press groundnut , get crude oil and oil cake

-Degumming:to make phosphatide absorb water and precipitated.

-First filter: to remove impurities and part of phosphatide

-Second filter: to remove phosphatide reaching national standard.

C. Big group groundnut →crushing →flaking →steam cooking →pressing → crude oil →degumming→ first filtering →Second filtering→edible groundnut oil

- Crushing : to crush groundnut into 4-6 pieces which fits flaking conditions

- Flaking : to flake crushed groundnut into thin and even pieces, thickness < 0.5mm

- Cooking , pressing until edile groundnut are same as above.

2. Groundnut oil extraction process

Pressed groundnut oil cake → Oil extractor→ Mixed oil→ Three evaporation→ Crude groundnut oil

|

wet meal → desolventizer → dry meal to package

- Oil extractor: using solvent N-hexane to extract oil from pressed oil cake

- Mixed oil/wet meal : after oil extractor, will get mixed oil with solvent and wet meal with solvent

- Three evaporation: using three muti-effective evaporators to transform solvent to gas which will be cooled down and collected by passing condensers.

- Desolventizer: to dry wet meal and evaporate solvent .

3. Groundnut oil refining process

Crude oil from oil extraction→ Degumming → Deacidification→Decoloration→ Deodorization→Refined groundnut oil

- Degumming: adding phosphoric acid (85%) to reduce gum and impurities inside crude oil

- Deacidification: adding alkali to neutralize free fatty acid , generates soapstock

- Decoloration: adding clay to bleach crude oil , clay quantity depends on quality of decoloration . Waste clay will be filtered .

- Deodorization: at high temperature vacuum conditions, using steam to remove odor impurities

if you want to know more the Groundnut /Peanut Oil Pressing, Peanut Oil Extraction and Oil Refining Plant, pls feel free to contact us.

Leave a message: Please fill in your information and we will contact you soon.