- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

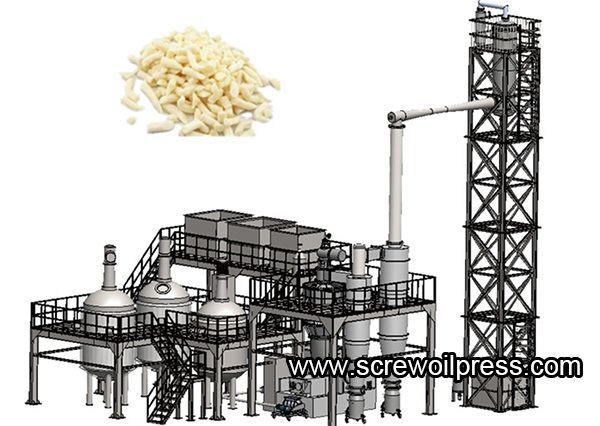

Oil Processing Plant

Palm Kernel Oil Press Machine Palm Oil Refinery Plant With Fractionation

Offer palm kernel Oil Processing Machine to our clients Fostered with rich industry experience and a highly experienced team of professionals, we are offering palm Oil Processing Machinery

SEND INQUIRY

Description

Palm Kernel Oil Press Oil Refinery Plant With Fractionation

We offer palm kernel Oil Processing Machine to our clients.Fostered with rich industry experience and a highly experienced team of professionals, we are offering palm Oil Processing Machinery.

A unique feature of the oil palm is that it produces two types of oil such as, red palm oil from the fruit flesh and palm kernel oil from the seeds.

Palm Kernel contains about 48% to 52% of oil. Its oil can be utilized for a wide range of industries and not only limited to food product.

The palm kernels, after separation from fibrous material, are processed for oil recovery using a solvent extraction process, as described above for seed oils. One hundred tonnes of FFB should produce approximately 2.5 tonnes of palm kernel oil, an oil rich in short-chain fatty acids.

The dried palm kernel (moisture 6%) passed through the elevator and screw conveyor to the first palm kernel press, and the palm kernel cake was pressed for the second time. The pressed palm kernel oil was filtered through a leaf filter and vacuum dried to remove water and stored in a palm kernel oil (CPKO) tank.

Cleaning section:

It is used for removing the iron impurities, stone, fiber and others. These impurities are bad for machines, especially for the palm kernel oil procrssing machine.

Crushing section:

Cruching section is important in palm kernel oil processing line. Because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required. Before crushing, palm kernel must be softened and dryed. The centrifugal crusher can break nuts and separate palm kernel out completely.

Palm kernel and nuts shell separation section:

Palm kernel and nuts shell separation machine is our new technology. It is on basis of the difference of relative density of palm kernel and shell. The palm kernel getting from this machine can be pressed by palm kernel oil processing machine directly.

Palm kernel drying section:

Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

Cooking section:

It is used for heating and cooking the crashing materials, to make is suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes.

Palm kernel oil pressing section:

Palm kernel oil pressing section is similar with usual oilseeds. The pre-pressing by palm kernel oil processing machine can obtain 1/4 palm kernel oil, and the residual oil need twice pressing.

Palm kernel oil filtering section:

After pressing, there is an essential section in palm kernel oil processing line, which is filtering section. After clarifying, the crude palm kernel oil will become more clear and with less impurities. If there is crude palm kernel oil refinery plant, we must filter the crude oil to avoid to jam the oil pipes during refining processes.

Palm Kernel Oil Refinery Plant Processing

Palm Kernel Oil Refinery Plant is specially designed and built for processing the Palm Kernel Oil. As you know, palm kernel oil is also referred to as PKO. This oil is obtained from the kernel seeds of the oil palm fruit. The process of extracting the palm kernel oil is through mechanical pressing.

Palm kernel oil is obtained from the kernel of the oil palm fruit. The oil composition of palm kernel oil is very different from that of the palm oil. Apart from the normal crude palm kernel oil, there are other 2 types of components obtained after palm kernel oil refining –

1) Palm Kernel Olein

This is the liquid component of the palm kernel oil obtained after refining.

2) Palm Kernel Stearin

This is the solid portion of the palm kernel oil obtained after refining.

Palm kernel oil, palm kernel olein and palm kernel stearin have various individual applications such as margarine making, confectioneries, bakery products, coffee whitener, biscuit cream; with little or no further processing. Palm Kernel Oil is also used in making of non-hydrogenated trans fat free margarine nowadays.

Sometimes when the refined palm kernel stearin is hydrogenated, it shows excellent results than cocoa butter. It is used as a substitute for this expensive cocoa butter. It has an excellent melting properties, Hydrogenated palm kernel oil has excellent melting properties along with good resistance to fat bloom and oxidation stress.

palm kernel oil press, palm oil extraction plant, palm oil refining machine, palm kernel oil refining plant, palm kernel oil processing plant, palm kernel oil expeller, palm kernel oil extruder, CPKO oil machine, palm kernel oil machine

Interested in Palm Kernel Oil Press Plant and Palm Kernel Oil Refinery Plant?

We offer palm kernel Oil Processing Machine to our clients.Fostered with rich industry experience and a highly experienced team of professionals, we are offering palm Oil Processing Machinery.

A unique feature of the oil palm is that it produces two types of oil such as, red palm oil from the fruit flesh and palm kernel oil from the seeds.

Palm Kernel contains about 48% to 52% of oil. Its oil can be utilized for a wide range of industries and not only limited to food product.

The palm kernels, after separation from fibrous material, are processed for oil recovery using a solvent extraction process, as described above for seed oils. One hundred tonnes of FFB should produce approximately 2.5 tonnes of palm kernel oil, an oil rich in short-chain fatty acids.

The dried palm kernel (moisture 6%) passed through the elevator and screw conveyor to the first palm kernel press, and the palm kernel cake was pressed for the second time. The pressed palm kernel oil was filtered through a leaf filter and vacuum dried to remove water and stored in a palm kernel oil (CPKO) tank.

Cleaning section:

It is used for removing the iron impurities, stone, fiber and others. These impurities are bad for machines, especially for the palm kernel oil procrssing machine.

Crushing section:

Cruching section is important in palm kernel oil processing line. Because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required. Before crushing, palm kernel must be softened and dryed. The centrifugal crusher can break nuts and separate palm kernel out completely.

Palm kernel and nuts shell separation section:

Palm kernel and nuts shell separation machine is our new technology. It is on basis of the difference of relative density of palm kernel and shell. The palm kernel getting from this machine can be pressed by palm kernel oil processing machine directly.

Palm kernel drying section:

Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

Cooking section:

It is used for heating and cooking the crashing materials, to make is suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes.

Palm kernel oil pressing section:

Palm kernel oil pressing section is similar with usual oilseeds. The pre-pressing by palm kernel oil processing machine can obtain 1/4 palm kernel oil, and the residual oil need twice pressing.

Palm kernel oil filtering section:

After pressing, there is an essential section in palm kernel oil processing line, which is filtering section. After clarifying, the crude palm kernel oil will become more clear and with less impurities. If there is crude palm kernel oil refinery plant, we must filter the crude oil to avoid to jam the oil pipes during refining processes.

Palm Kernel Oil Refinery Plant Processing

Palm Kernel Oil Refinery Plant is specially designed and built for processing the Palm Kernel Oil. As you know, palm kernel oil is also referred to as PKO. This oil is obtained from the kernel seeds of the oil palm fruit. The process of extracting the palm kernel oil is through mechanical pressing.

Palm kernel oil is obtained from the kernel of the oil palm fruit. The oil composition of palm kernel oil is very different from that of the palm oil. Apart from the normal crude palm kernel oil, there are other 2 types of components obtained after palm kernel oil refining –

1) Palm Kernel Olein

This is the liquid component of the palm kernel oil obtained after refining.

2) Palm Kernel Stearin

This is the solid portion of the palm kernel oil obtained after refining.

Palm kernel oil, palm kernel olein and palm kernel stearin have various individual applications such as margarine making, confectioneries, bakery products, coffee whitener, biscuit cream; with little or no further processing. Palm Kernel Oil is also used in making of non-hydrogenated trans fat free margarine nowadays.

Sometimes when the refined palm kernel stearin is hydrogenated, it shows excellent results than cocoa butter. It is used as a substitute for this expensive cocoa butter. It has an excellent melting properties, Hydrogenated palm kernel oil has excellent melting properties along with good resistance to fat bloom and oxidation stress.

palm kernel oil press, palm oil extraction plant, palm oil refining machine, palm kernel oil refining plant, palm kernel oil processing plant, palm kernel oil expeller, palm kernel oil extruder, CPKO oil machine, palm kernel oil machine

Interested in Palm Kernel Oil Press Plant and Palm Kernel Oil Refinery Plant?

Leave a message: Please fill in your information and we will contact you soon.