- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

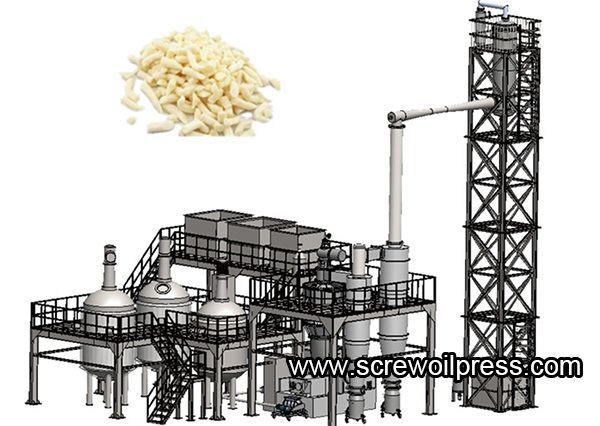

Oil Processing Plant

Mustard Oil Press Plant Mustard Oil Extraction Plant Oil Refinery Machine

Manufacturer of mustard oil mill machinery, small to large mustard oil mill plant exporter in China We provide our customers a complete service package for turnkey mustard oil extraction plant and mustard oil refinery machinery

SEND INQUIRY

Description

Mustard Oil Extraction Plant and Mustard Oil Refinery Machinery

Mustard seeds, also known as rapeseed and canola seed. Mustard seed contains 38% – 40% of oil content. Major producers of mustard seeds include India, Pakistan, Canada, Nepal, Hungary, Great Britain and the United States. Brown and black mustard seeds return higher yields than their yellow counterparts.

the common machines required for mustard seed oil mill plant including Bucket Elevator, Screw Conveyor, Seed Cleaner, Oil Expeller, Crude mustard oil tanks, Filter press machine with Pump, Filtered oil tanks and Volumetric filling machine.

Mustard Oil Mill Plant Process -Mustard Seed Oil Expeller

mustard/rapeseed oil mill plant involves the following steps : seed cleaning, oil pressing, oil filtration and oil filling.

ZX Screw Oil Press Mill Parameters

Mustard oil solvent extraction machine main process:

(1) The pressed cake (form prepressed workshop) send to cooking vegetable edible oil extraction machinery by the scraper conveyor. Mixed oil will extracted from the pressed cooking vegetable edible oil cake by the solvent. After this step, we will get cooking meal and mixed oil.

(2) Cooking vegetable edible oil meal will sent to the toaster. Through the toaster, the solvent will separate from the meal. The solvent goes to condenser and is reused to cooking vegetable edible oil extraction machinery.

(3) Mix oil from the cooking vegetable edible oil machinery enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is reused to cooking vegetable edible oil extraction machinery.

The vegetable oil obtained by musterd oil pretreatment and pressing machine or mustard oil solvent extraction machine,which contains water, mechanical impurities, fat-soluble impurities, peptizing impurities, trace impurities, etc. ,failed to meet the edible standards.

Refining refers to remove the impurities in crude oil, to get a good quality of the first class of edible oil.

Types of mustard oil refining machine:

1.Batch type mustard oil refining machine,suitable for small capacity like 1-2-3-5-10TPD

2.Semi-continuous mustard oil refining machine,suitable for medium capacity like 10-50TPD

3.Full continuous mustard oil refining machine,suitable for large capacity above 30TPD

Main process of mustard oil refining machine:

1. Degumming. In this step gums in crude oil are removed by hydration with the help of phosphoric acid.

2. Neutralization. In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

3. Bleaching. During bleaching, unwanted pigments are adsorbed physically and oil will become much clearer.

4. Deodorization. Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

If you are interested in setting up an mustard seeds oil extraction plant, please let us know and we will be pleased to send you the list of most suitable machine and equipment and latest quotation. Just feel free to contact us.

Mustard seeds, also known as rapeseed and canola seed. Mustard seed contains 38% – 40% of oil content. Major producers of mustard seeds include India, Pakistan, Canada, Nepal, Hungary, Great Britain and the United States. Brown and black mustard seeds return higher yields than their yellow counterparts.

the common machines required for mustard seed oil mill plant including Bucket Elevator, Screw Conveyor, Seed Cleaner, Oil Expeller, Crude mustard oil tanks, Filter press machine with Pump, Filtered oil tanks and Volumetric filling machine.

Mustard Oil Mill Plant Process -Mustard Seed Oil Expeller

mustard/rapeseed oil mill plant involves the following steps : seed cleaning, oil pressing, oil filtration and oil filling.

ZX Screw Oil Press Mill Parameters

| Model | Pressing Capacity | Residual Oil in cake | Motor Power | Dimensions(L×W×H) | N.W. |

| HZX18B | 6--10 t/d | 4-11 % | 22+3+2.2 kw | 2900×1850×2640 mm | 3500 kg |

| HZX24 | 15-25 t/d | 7-9 /10-15% | 30+5.5+3.0 kw | 3180x1850x3940mm | 6300 kg |

| HZX28 | 40-60 t/d | 7-9 % | 55+11+4.0 kw | 3740×1920×3800 mm | 10000 kg |

| HZX32 | 80-100 t/d | 8-10 % | 90+7.5+1.5 kw | 4800×2970×3050 mm |

Mustard oil solvent extraction machine main process:

(1) The pressed cake (form prepressed workshop) send to cooking vegetable edible oil extraction machinery by the scraper conveyor. Mixed oil will extracted from the pressed cooking vegetable edible oil cake by the solvent. After this step, we will get cooking meal and mixed oil.

(2) Cooking vegetable edible oil meal will sent to the toaster. Through the toaster, the solvent will separate from the meal. The solvent goes to condenser and is reused to cooking vegetable edible oil extraction machinery.

(3) Mix oil from the cooking vegetable edible oil machinery enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is reused to cooking vegetable edible oil extraction machinery.

The vegetable oil obtained by musterd oil pretreatment and pressing machine or mustard oil solvent extraction machine,which contains water, mechanical impurities, fat-soluble impurities, peptizing impurities, trace impurities, etc. ,failed to meet the edible standards.

Refining refers to remove the impurities in crude oil, to get a good quality of the first class of edible oil.

Types of mustard oil refining machine:

1.Batch type mustard oil refining machine,suitable for small capacity like 1-2-3-5-10TPD

2.Semi-continuous mustard oil refining machine,suitable for medium capacity like 10-50TPD

3.Full continuous mustard oil refining machine,suitable for large capacity above 30TPD

Main process of mustard oil refining machine:

1. Degumming. In this step gums in crude oil are removed by hydration with the help of phosphoric acid.

2. Neutralization. In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

3. Bleaching. During bleaching, unwanted pigments are adsorbed physically and oil will become much clearer.

4. Deodorization. Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

If you are interested in setting up an mustard seeds oil extraction plant, please let us know and we will be pleased to send you the list of most suitable machine and equipment and latest quotation. Just feel free to contact us.

Leave a message: Please fill in your information and we will contact you soon.