- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

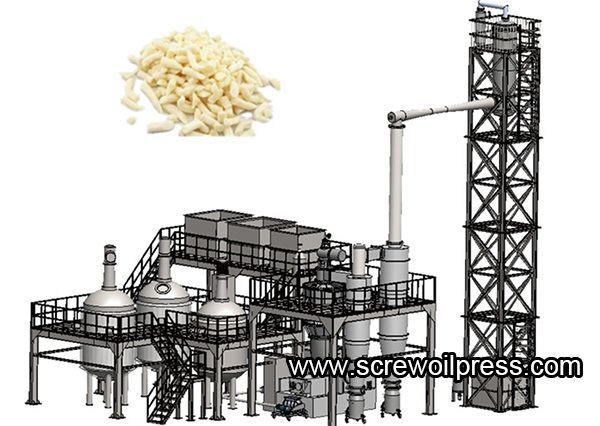

Oil Processing Plant

Extra Virgin Olive Oil Extraction Line Plant

Extra vrigin olive oil,also called EVOO, is extracted from healthy and fresh olives, purely by the mechanical means such as centrifuge decantation and separation Quality control index:acidity,peroxide value,Absorbency in ultra-voilet,Fatty Acid Compositi

SEND INQUIRY

Description

Extra Virgin Olive Oil Extraction Line Plant

What is extra-virgin olive oil?

Extra Virgin Olive Oil (EVOO) is the natural oil that is produced when quality olives that have been picked straight off the tree are processed, as soon as possible, without the use of chemicals or excessive heat.

The extra virgin olive oil that is produced in this manner is clean and healthful – exactly as nature intended – and not adulterated or added to in any way. The oil has not been treated other than through washing, centrifuging and filtering.

Olive Groves of Extra Virgin Olive Oil

It is an all-natural food.

Advantages in Manufacturing and Extracting Olive Oil:

Very low fresh water consumption and a small amount of resulting wastewater

First-class oil quality and a high yield of raw materials

Low use of personnel because of continuous and automatic operation

Low energy and process costs

Long service life of the machines and comparatively low maintenance requirements

According to the product characteristics and production process, the main steps of the process design are: (1) defolate, (2) washing, (3) crushing, (4) fusion, (5) decantation, (6) separation, (7) ) storage, (8) filling and packing

1. Defolate : The olive fruit after picked is transferred through the belt conveyor equipped with a wind sorter to remove leaves, to avoid chlorophyll oxidation and affect the quality of the oil. Branches and leaves separated fomfruit by fan.

2. Washing : Wash the fruit with circulating water to remove dust, sand and a small amount of leaves. Usually, 2 tons of water wash 5 tons of fruit.

3. Crushing : Crush the washed olive fruit to get fruit pulp by a hammer mill. The mesh size is about 6 mm and the beating speed is about 2500-3000 rpm.

4. Fusion : The crushed pulp is transferred to a horizontal ribbon mixer through a screw pump for mixing, and the oil droplets are formed by stirring with a ribbon mixer. The better mixing time is about 30 minutes,temperature about 30 degrees and the crusher rotation speed is 30-50 revolutions. The horizontal mixer is equipped with jacket for water cooling.

5. Decanting : The blended oil water and pomace are transported by a screw pump to the decanter centrifuge for oil,water and pomace separation. Two or Three-phase separation decanter and the vertical disc centrifuge are usually selected according to the process requirements. The three-phase separation process requires to add a large amount of process water and finally separate the oil, waste water and pomace; finally the amount of waste water is large; the two-phase separation directly separates the pulp into oil and pomace, no need to add water, but the water content of the pomace is high,more than 60%, further separation is required.

6. Separation : The separated oil phase also contains a small amount of water, which is required further separation by a vertical high-speed centrifuge, and the centrifuge speed is about 6600-8000 rpm. About 10-15% of water is added during the separation.

7. Storage : The centrifugally separated oil is pumped into big stainless steel storage tanks for storage to avoid light and heat.Usually the stainless steel storage tank is filled with nitrogen gas and olive oil is stored at a constant temperature and filled N2 state.

8. Filling : The oil in the tank periodically releases a small amount of water and oil foot. Then, it is dispensed into glass bottles and sealing, labeling and packing etc. for sale in market.

What is extra-virgin olive oil?

Extra Virgin Olive Oil (EVOO) is the natural oil that is produced when quality olives that have been picked straight off the tree are processed, as soon as possible, without the use of chemicals or excessive heat.

The extra virgin olive oil that is produced in this manner is clean and healthful – exactly as nature intended – and not adulterated or added to in any way. The oil has not been treated other than through washing, centrifuging and filtering.

Olive Groves of Extra Virgin Olive Oil

It is an all-natural food.

Advantages in Manufacturing and Extracting Olive Oil:

Very low fresh water consumption and a small amount of resulting wastewater

First-class oil quality and a high yield of raw materials

Low use of personnel because of continuous and automatic operation

Low energy and process costs

Long service life of the machines and comparatively low maintenance requirements

According to the product characteristics and production process, the main steps of the process design are: (1) defolate, (2) washing, (3) crushing, (4) fusion, (5) decantation, (6) separation, (7) ) storage, (8) filling and packing

1. Defolate : The olive fruit after picked is transferred through the belt conveyor equipped with a wind sorter to remove leaves, to avoid chlorophyll oxidation and affect the quality of the oil. Branches and leaves separated fomfruit by fan.

2. Washing : Wash the fruit with circulating water to remove dust, sand and a small amount of leaves. Usually, 2 tons of water wash 5 tons of fruit.

3. Crushing : Crush the washed olive fruit to get fruit pulp by a hammer mill. The mesh size is about 6 mm and the beating speed is about 2500-3000 rpm.

4. Fusion : The crushed pulp is transferred to a horizontal ribbon mixer through a screw pump for mixing, and the oil droplets are formed by stirring with a ribbon mixer. The better mixing time is about 30 minutes,temperature about 30 degrees and the crusher rotation speed is 30-50 revolutions. The horizontal mixer is equipped with jacket for water cooling.

5. Decanting : The blended oil water and pomace are transported by a screw pump to the decanter centrifuge for oil,water and pomace separation. Two or Three-phase separation decanter and the vertical disc centrifuge are usually selected according to the process requirements. The three-phase separation process requires to add a large amount of process water and finally separate the oil, waste water and pomace; finally the amount of waste water is large; the two-phase separation directly separates the pulp into oil and pomace, no need to add water, but the water content of the pomace is high,more than 60%, further separation is required.

6. Separation : The separated oil phase also contains a small amount of water, which is required further separation by a vertical high-speed centrifuge, and the centrifuge speed is about 6600-8000 rpm. About 10-15% of water is added during the separation.

7. Storage : The centrifugally separated oil is pumped into big stainless steel storage tanks for storage to avoid light and heat.Usually the stainless steel storage tank is filled with nitrogen gas and olive oil is stored at a constant temperature and filled N2 state.

8. Filling : The oil in the tank periodically releases a small amount of water and oil foot. Then, it is dispensed into glass bottles and sealing, labeling and packing etc. for sale in market.

Leave a message: Please fill in your information and we will contact you soon.